雷尼绍的RH200系列是一种非接触式光栅系统。紧凑型读数头配有LED安装指示灯,抗污能力优异的独特光学滤波系统,以及分辨率达10 nm的内置细分电路。 RH200可提供经验证的可靠性、性能和价值,因此成为最常用的光栅系统之一。 RH200可读取20 µm栅距的RGS20镀金钢带栅尺并选择输出行业标准1Vpp模拟或RS442数字信号。 RGS20适合安装在金属、花岗岩、陶瓷和复合材料等大多数常见的工程材料上。可使用特殊配方预涂不干胶和环氧胶粘合的“端压片”将栅尺固定在轴基体上。这种安装方式可确保栅尺与

Renishaw's RH200 series is a non-contact grating system. The compact readhead features an LED-mounted indicator light, a unique optical filtering system with excellent dirt resistance, and a built-in subdivision circuit with a resolution of 10 nm. The RH200 offers proven reliability, performance and value, making it one of the most commonly used grating systems.

The RH200 can read RGS20 gold-plated steel tape scales with a 20 μm pitch and selects the industry standard 1Vpp analog or RS442 digital signal. The RGS20 is suitable for installation on most common engineering materials such as metals, granite, ceramics and composites. The scale can be fixed to the shaft base using a special formulation of pre-coated self-adhesive and epoxy bonded "end tabs". This type of installation ensures that the difference in movement between the scale and the base is almost zero, even if large temperature fluctuations occur. ? A number of practical examples have proven that RH200 series gratings can be easily handled for applications that are challenging for most other open gratings. Many of the world's leading linear motion system original equipment manufacturers (OEMs) have installed this series of grating systems, covering applications such as metrology, machine tools, electronics, semiconductors and flat panel displays.

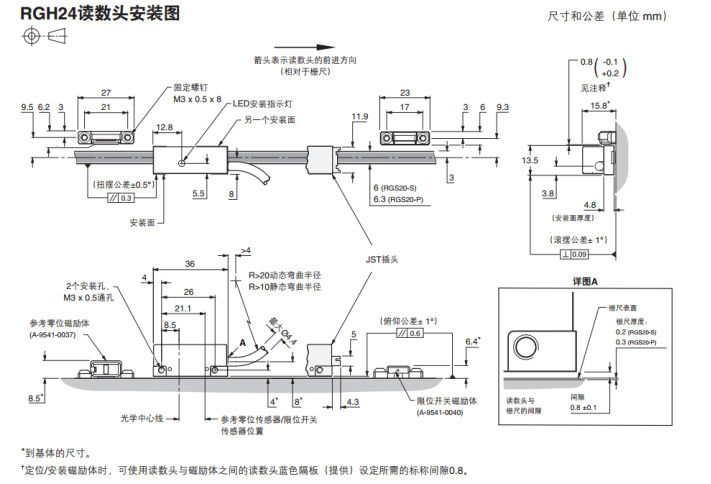

RH200 readhead:

• Compact and lightweight

• Open non-contact optical system

• Built-in subdivision circuit

• Industry standard digital and analog signal options

• Resolution from 5 μm to 10 nm

• Built-in reference zero or limit Sensors

• Integrated LED mounting indicator RGS20 scale:

• Flexible application, can be cut on demand

• Lengths from 100 mm to 50 m

• Protective film or sturdy polyester coating option for strong solvents Applications

• Quick and accurate installation

• Can be attached to most common engineering materials

• Self-contained tape on the back

• Mounting tool can be used to mount the scale with shaft movement