Characteristics of SMAC Actuators

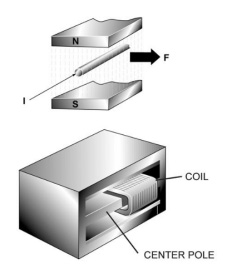

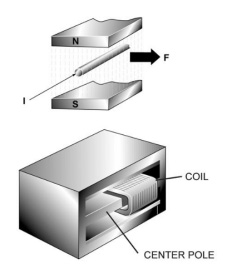

Characteristics of SMAC ActuatorsSMAC actuator can be said to be coil moving actuator or voice coil actuator. Its principle is the same as that of a permanent magnet horn. The coil is covered by a magnet chamber and the magnetic field is generated by current passing through the coil. Therefore, the company's mobile coil actuator is the ideal linear motor.

The sum of forces produced depends on the equation. F = N I B

F Is the power generated.

N It's the winding number of coils.

I Current through the coil

B It's magnetic flux.

Because we can control the current, we can control the output of power more accurately.

Advantages of Coil Moving Technology

•Low moving mass mobile coil actuators mean high moving acceleration and speed. On the contrary, most linear actuators use high moving mass mobile magnet technology.

•Safe and efficient: Operating at low current, e.g. 1.5 ampere 24 volt DC;

•Operating without compressed air: No expensive compressed air equipment is required. There is no need to consume gas or deal with ventilation problems. Because there is no compressed gas, the pollution of air particulate molecules is reduced, and the running noise is less than 55 dB;

•There is no need for a pneumatic valve, and there is no fluctuation of gas pressure affecting the output of power.

Uniqueness and advantages of SMAC

• Programs can be edited for position, acceleration and power;

• Direct drive = no backlash, high precision and good repeatability;

• Micron resolution (from 5 microns to 100 nm);

• Power Control = Soft Landing: Lightly apply pressure without damaging materials or parts;

• Mean time between failures of more than 250 million cycles = long operating life.

SMAC actuators provide a very flexible application

• There is a glass ruler and an optical test head (without contact loss) that can be combined with a position measurement system;

• Ability to switch power, position and speed modes at any time;

• Quickly change when "System Job" is adjusted;

• Control and detect continuous output force;

• Digital and analog input/output channels;

• Our linear motor is a servo system, so you can edit the program to decelerate quickly and smoothly. Mechanical shock can be completely avoided;

• In addition to the above advantages, prices are also competitive.

Programmable and soft landing

Programmable features

The actuators are fully programmable in terms of force, acceleration and speed. It allows users to quickly and flexibly operate and convert a wide range of products at the push of a button. A variety of operational profiles (programs) can be stored or pre-set in the SMAC controller. In addition, you can switch between 3 different modes:

Power mode: The power mode is an open loop, using the encoder without feedback; the actual position is still monitored but has no effect on the output.

Speed mode: The speed mode allows the actuator's axis to move at a set speed, acceleration, force, and direction. Often used in the unique "soft landing" feature.

Position mode: The position mode allows the actuator's axis to move multiple positions depending on the stroke size and acceleration, speed force, and the like. Absolute, relative, and "learned" position movements can be made.

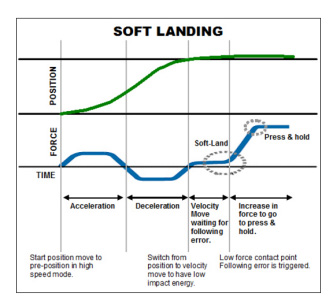

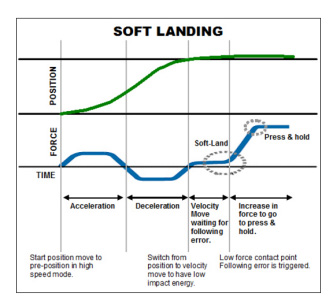

What is the soft landing function?

What is the soft landing function?Soft landing means that the axle or claw of the actuator approaches the surface of the part in a programmable, high-speed and low-force manner. This unique function is very helpful for the assembly of precision fragile or high unit price parts.

In the speed mode, the object is approached with programmable low power, and the position is continuously monitored for errors. Once the contact starts, the position error will occur until the error value reaches the set value of the program, and the position of the axis will remain on the surface of the object.

•Less than 10 kg - Soft contact

•Identifying objects/obstacles

•Usually used for:

•Precision fetching and placing application

•Measurable materials that are easily damaged or distorted

•Switch or Material Testing

•Other more

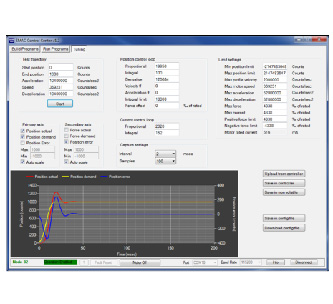

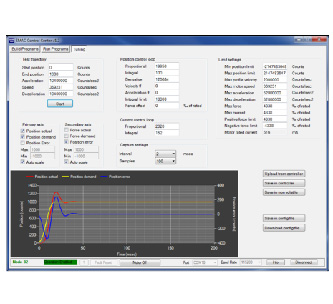

SMAC Control Software - Graphic User Interface Program (GUI) Program Editing Tool

Our control software is a graphical interface, which can configure and adjust the LCC-10 controller of SMAC. This is a simple way to create motion programs (macro combinations). You can create a program and detect four variables while the program is running, and fine-tune the program loop according to the detection results.

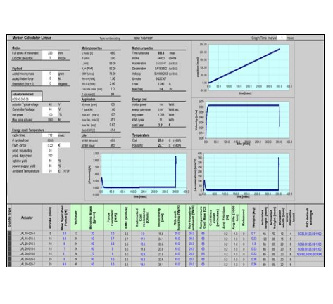

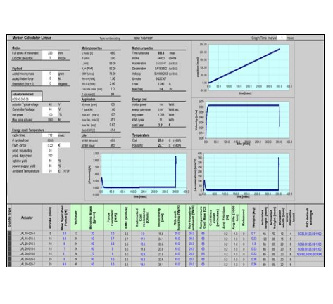

Computation table

Computation table

Our calculation table is presented in Excel software to help you find the correct actuator model. It also makes it easier for you to edit LAC-1 or LAC-25 software.

Characteristics of SMAC Actuators

Characteristics of SMAC Actuators